Fɛn minnu bɛ kɛ ka fɛnw dilan .

Electrostatique coating ka ɲɛsin abrasive distribution tigitigi ma .

Micron diamond abrasives are directionally aligned under a high-voltage electrostatic field, ensuring consistent abrasive exposure, enhanced cutting power, and uniform surface finish.

Fɛn minnu bɛ se ka kɛ ka ɲɛ, olu bɔli ni sen caman ye .

K’a sababu kɛ dumuni dɔɔni dunni ye, a ka kan ka kɛ ni fɛn dɔw ye minnu bɛ kɛ ka fɛnw sɔgɔ, olu ka kan ka dɔgɔya kosɛbɛ, o bɛ dɔ bɔ kosɛbɛ baarakɛcogo waati la ani fɛnw musakaw la minnu bɛ kɛ ka fɛnw sɔgɔ.

A ka ɲi nɛgɛ gɛlɛnw ni fiyɛlilanw na minnu bɛ kɛ ka sumaya .

A dabɔra kɛrɛnkɛrɛnnenya la fɛnw kama minnu ka gɛlɛn kosɛbɛ i n’a fɔ tungsten steel ani hard alloy rollers, o filimu dafalen don contour ani geometry dafalen kama.

Finishing min bɛ i n’a fɔ filɛlikɛlan, o ye fɛnw ye minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ .

A bɛ yɔrɔw di minnu ka nɔgɔn kosɛbɛ, minnu bɛ yeelen bɔ u la, minnu bɛ kɛ ka fɛnw ni jirisunw kɛ, o b’a to a ka ɲi kosɛbɛ baarakɛcogo la min bɛ ɲini ka ɲɔgɔnkanu dɔgɔya ani ka ɲɛnayeli kɛcogo ɲuman sɔrɔ.

Poliyesitɛri min bɛ mɛn sen na ni a jɔli da wulilen ye .

A bɛ fanga ni fɛn caman sɛgɛsɛgɛli kɛ teliya la lapping masinw na, ka sɔrɔ da wulilen bɛ dɔ bɔ a dacogo la, ka ɲɛnamaya janya, ani ka sɔgɔli kɛcogo ɲɛ.

Product Paramɛtɛrɛw .

| A ɲɛfɔli . |

Ɲɛfɔli |

| Product tɔgɔ . |

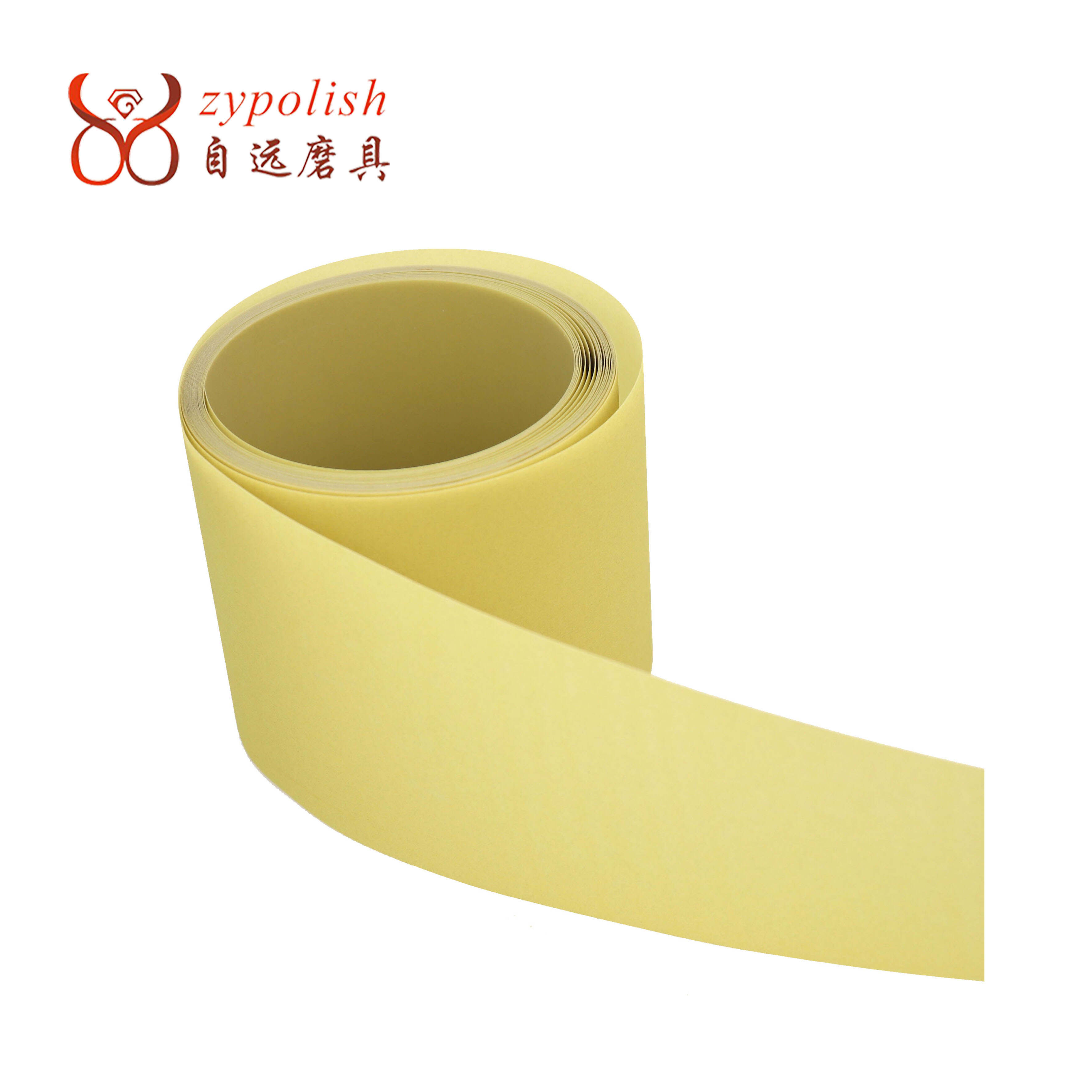

Diamant microfinishing film rollo . |

| Materiel abrasif . |

Diamant . |

| Backing Material . |

Film polyester fanga ka bon . |

| Backing suguya . |

Coat da wulilen . |

| Datugulan fɛɛrɛ . |

Electrostatique ka fini . |

| Micron kalasi bɛ sɔrɔ . |

60, 40, 30, 20, 15, 9, 6, 3, 1 Micron . |

| Kulɛri suganditaw . |

finman, jɛman, bulu, oranjɛ, rose . |

| Kundama |

101,6mm × 15m (hakɛw bɛ sɔrɔ) |

| Mariki |

Zypolish . |

| A tali ladilikan . |

Rouleau, Crankshaft, Camshaft, Cermier & Tungsten Drill Bit Polishing |

Aplikasi .

Camshafts ni crankshafts ka sɔgɔli tigitigi .: : .A bɛ muɲuli gɛlɛn di ani fini dafalen min ka kan ka kɛ motɛri yɔrɔw la.

Roller Polishing in Printing and Coating Industries .: : .A ka ɲi kosɛbɛ seramiki, fɛn gɛlɛn, walima a bɛ kɛ ni wuluwulu ye min bɛ kɛ ni fiyɛ ye.

Baarakɛminɛn ani Die Finishing .: : .A bɛ ultra-fine surface di tungsten steel drill bits ani dies kan.

Mirror Polishing of non-ferous metal yɔrɔw .: : .A bɛ fini yeelenba sɔrɔ aesthetic ani functional components.

Furakɛcogo ɲuman aerospace ani furakɛli minɛnw dilanni na .: : .A bɛ baara kɛcogo ɲuman ni a lakanani sabati.

A kɛcogo ɲumanw .

A bɛ kɛ ka camshaft lobes lapping kɛ min nafa ka bon kosɛbɛ walasa ka dɔ bɔ ɲɔgɔnkanu na ani ka motɛriw ka baara kɛcogo ɲɛ.

A bɛ fɔ ka ɲɛsin mirror polish-coated rollers ma sɛbɛnni ni ɛntɛrinɛti baarakɛyɔrɔw la.

A ka ɲi kosɛbɛ ka ɲɛsin mansinw laban ma minnu bɛ kɛ ka tulu filimuw kunbɛn ani ka u muɲu.

A bɛnnen don kosɛbɛ tungsten carbide drill bits ma walasa ka baarakɛminɛnw ɲɛnamaya ni u tiɲɛni janya.

A dafalen don ka ɲɛsin sanfɛla labɛnni ma nɛgɛ gɛlɛnw ni yɔrɔw la minnu tɛ nɛgɛ ye, minnu bɛ fini nɔgɔlenw de wajibiya.

komandi sisan .

An ka diamant microfinishing film roll ye injiniyɛri ye walasa ka a ɲɛfɔ ka ɲɛ, ka teliya ani ka kɛ ɲɔgɔn fɛ. I mana kɛ ka camshafts, seramiki rollers, walima tungsten steel tools ban, nin fɛn in bɛ nafa danmadɔw di ani ka baara kɛ waati jan kɔnɔ. A bɛ sɔrɔ micron suguya caman na ani a kulɛriw la walasa ka a dɔn nɔgɔya la. Aw bɛ se ka anw sɔrɔ sisan walasa ka sɔngɔ caman sɔrɔ, ka kɛɲɛ ni mɔgɔw sago ye, walima ka fɛɛrɛw lajɛ.